Certification

Mid-West Forge Corporation was registered to QS9000 in 1999. In April 2018, Mid-West Forge Corporation received its IATF 16949 certification from Smithers Quality Associates, Inc.

Mid-West Forge Corporation is committed to performing and maintaining world class excellence in the manufacturing of drive-train components in conjunction with pollution prevention. We continually strive to meet or exceed customer quality and delivery requirements while maintaining a safe and environmentally friendly workplace that complies with all relevant regulatory requirements. Mid-West Forge endeavors to continually improve our comprehensive Quality Operating System while providing a work environment that is free from recognizable hazards and protects the environment by establishing and maintaining our Environmental, Health and Safety Management System.

![]()

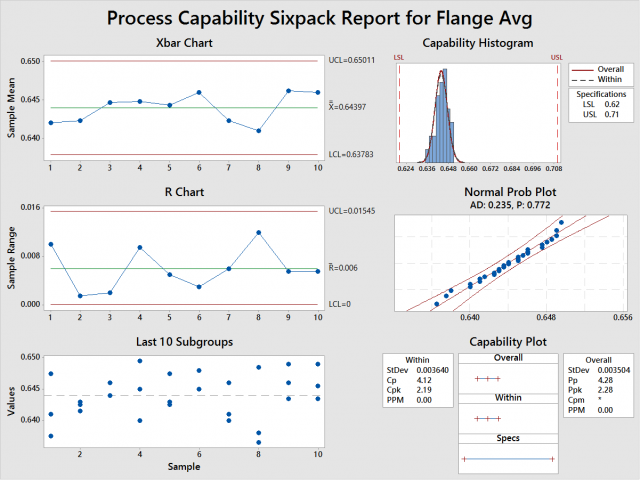

Gaging and SPC

Every part that is produced is inspected utilizing an automatic gage and inspection system. A networked inspection configuration processes real time SPC information throughout the plant.

![]()

Metallurgical Lab

Our fully equipped metallurgical lab allows us to meet all of your testing requirements. We are capable of performing micro hardness testing with both Vickers and Koop capabilities, Rockwell hardness testing including superficial scales, Brinell hardness testing, Microstructure analysis, grain flow and size analysis, crack detection via magnetic particle inspection, defect investigation, and dimensional examination. The lab includes a precision saw, automatic polishing station, acid etching booth, Unimet Metallograph with photographic capability, and optical measuring equipment.